Polysiloxanes (Silicones)

PROPERTIES

Silicone polymers or polydialkylsiloxanes are an important class of inorganic polymers that find many industrial uses. They are known for their outstanding temperature and oxidative stability, excellent low temperature flexibility, and high resistance to weathering and many chemicals. These polymers also have low surface tension and are capable of wetting most surfaces.

The name silicone usually refers to organosilicon polymers with the general structure -[Si(R2)-O]- where R = -CH3 is called poly(dimethyl siloxane) which is often abbreviated as PDMS:

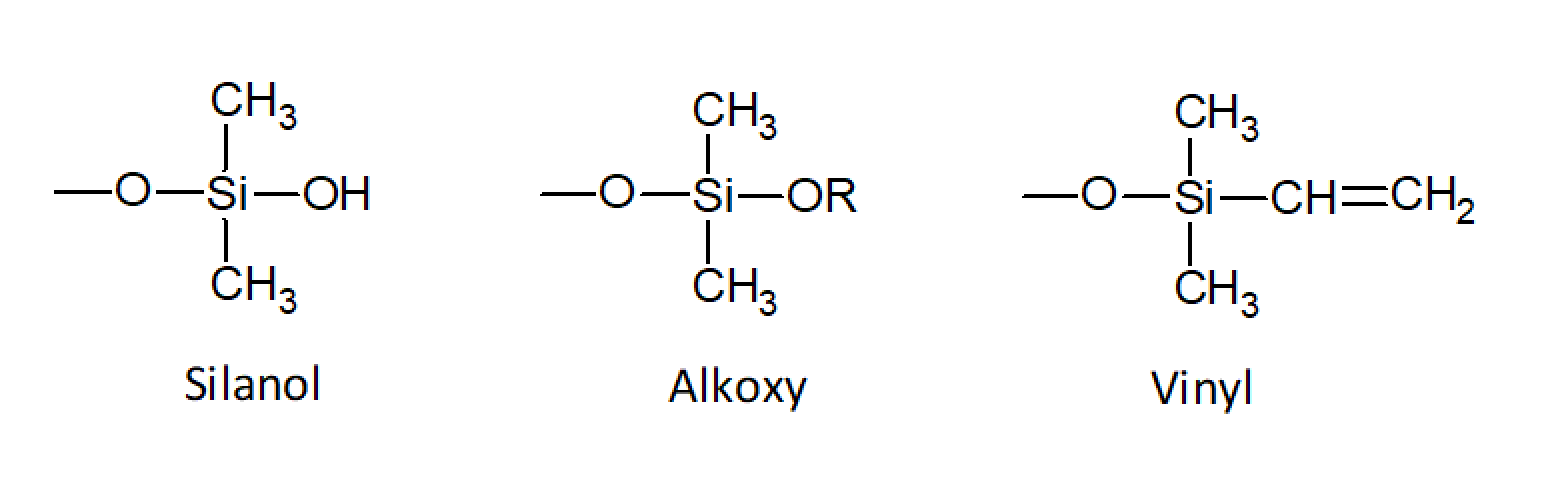

The methyl groups along the chain can be substituted by many other groups (e.g., ethyl, phenyl, vinyl, etc.) which allows for tailoring the chemical, mechanical and thermophysical properties for a wide variety of applications. The (terminal) silanol or alkoxy groups render PDMS susceptible to condensation under both mild acid and base conditions and have to be converted to alkyl groups if non-reactive (liquid) silicones are desired, whereas resins with alkoxy, hydroxyl, vinyl, and other crosslinkable groups are intermediates for room temperature vulcanizable silicones (RTVs) that are converted into various silicone products.

Silicone polymers possess an inorganic -(Si-O)- backbone similar to silicates which are associated with high surface energy. The Si-O bonds are strongly polarized and without side groups, should lead to strong intermolecular interactions. However, the nonpolar methyl groups shield the polar chain backbone. In other words, when the methyl groups point to the outside, silcones form hydrophobic films with good release properties, particularly if the film is cured after application. In fact, PDMS has one of the lowest critical surface tension of all polymers which is in the range of 20 to 25 mN/m and comparable to that of Teflon (PTFE). Thus polyalkylsiloxanes are capable of wetting most surfaces, unless some of the methyl groups are replaced by more polar groups.

Due to the low rotation barriers, most siloxanes are very flexible. For example, the rotation energy around a CH2-CH2 bond in polyethylene is about 13.8 kJ/mol but only 3.3 kJ/mol around a Me2Si-O bond, corresponding to a nearly free rotation.1,2 Furthermore, chain-to-chain interaction is rather week due to the low cohesive energy, and the distance between adjacent chains is noticeably larger in silicones than in alkanes which also contributes to the great flexibility of silicones. Due to great flexibility of the chain backbone, the activation energy of viscous flow is very low, and the silicone viscosity is less dependent on temperature compared to hydrocarbon polymers.1

Despite a very polar backbone, silicones can be compared to paraffin, with a low critical surface tension of wetting. In fact, silicones have a critical surface tension of wetting that is higher than their own surface tension. Thus, silicones are capable of wetting themselves, a property that results in good film formation and good surface covering. The low intermolecular interactions in silicones have many other consequences. For example, the glass transition temperatures are very low (e.g., 150 K for a polydimethylsiloxane compared to 200 K for polyisobutylene, which is the analogue hydrocarbon.) Due to the high free volume, most gases have a high solubility and high diffusion coefficient in silicones. That is, silicones have a high permeability to oxygen, nitrogen and water vapor.

Many other groups like phenyl, vinyl, alkyl, or trifluoropropyl can substitute the methyl groups along the polymer backbone which leads to many unique properties and allows their use in a broad range of fields. One general drawback of the presence of other organic groups along the chain backbone is the reduction of the polymer’s thermal stability. But with these substitutions, many other properties can be (greatly) improved. For example, a small percentage of phenyl groups along the chain reduces the tendency to crystallization and allows the polymer to remain flexible even at very low temperatures. The phenyl groups also increase the refractive index. Trifluoropropyl groups along the chain change the solubility parameter of the polymer from approximately 15.5 MPa1/2 to 19.5 MPa1/2, which reduces the swelling of silicone elastomers in aliphatic and aromatic solvents. Silicone copolymers can also be prepared with excellent surfactant properties, with the silicone as the hydrophobic part.

Synthesis & Crosslinking of Silicones

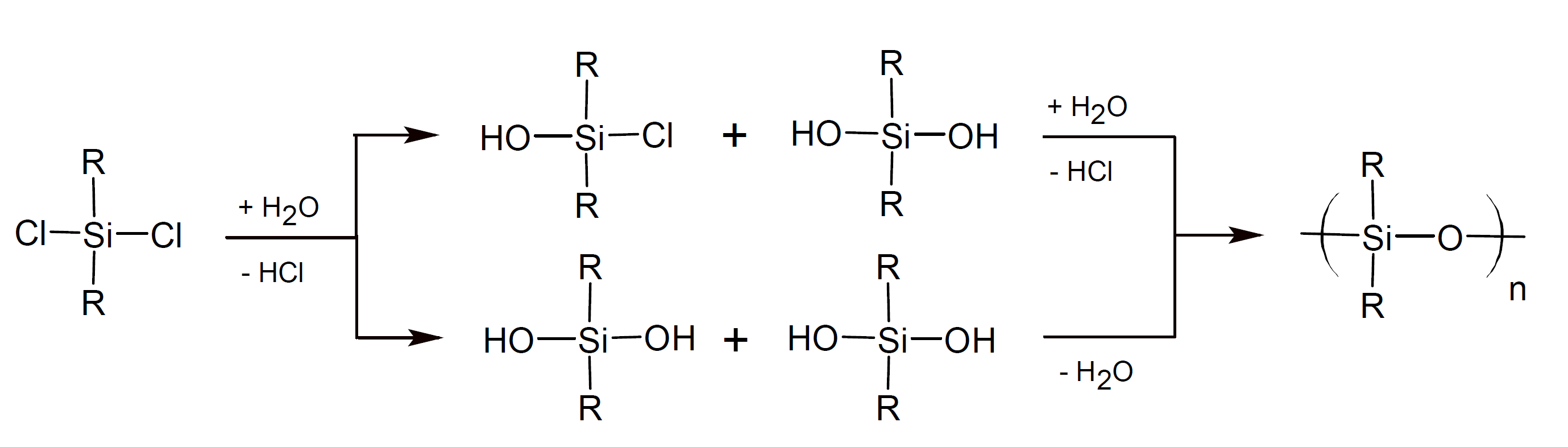

Silcones can be prepared by hydrolysis of dichlorosilanes in the presence of an excess of water. This reaction is exothermic and yields in a first step disilanols, Me2Si(OH)2, which then form linear and cyclic oligomers by inter- and intramolecular condensation catalyzed by the released hydrochloric acid, HCl:

The oligomers are separated from the acidic aqueous layer, washed

with water, and then neutralized and dried. The linear and cyclic oligomers obtained by hydrolysis of the dialkyldichlorosilanes are

typically of relative low molecular weight are

often further condensed (linear form) or polymerized (cyclic form) to yield

polymers of appropriate chain length. In some cases, the reaction mixture includes trichlorosilanes to

increase the molecular weight and to achieve crosslinking.

The

average molecular weight and the ratio of cyclic and

linear oligomers in the silicone resin mixture depend on the type of substituents along the chain and on the reaction conditions

such as monomer concentration, temperature, pH, and type of solvent.

For example, large and bulky side groups shift the equilibrium

to the linear form and basic conditions favor higher molecular weight oligomers.

Chlorosilanes can be converted to many other silane monomers and silicone oligomers. For example, reactive alkoxy and vinyl end groups can be formed by the reaction of chlorosilanes with alcohols and vinylmethylsiloxanes:

These oligomers and monomers can be further

modified to produce a large number of products such as

room temperature and moisture curing silicone rubbers that find uses in silicone adhesives,

coatings, sealants, and caulks.

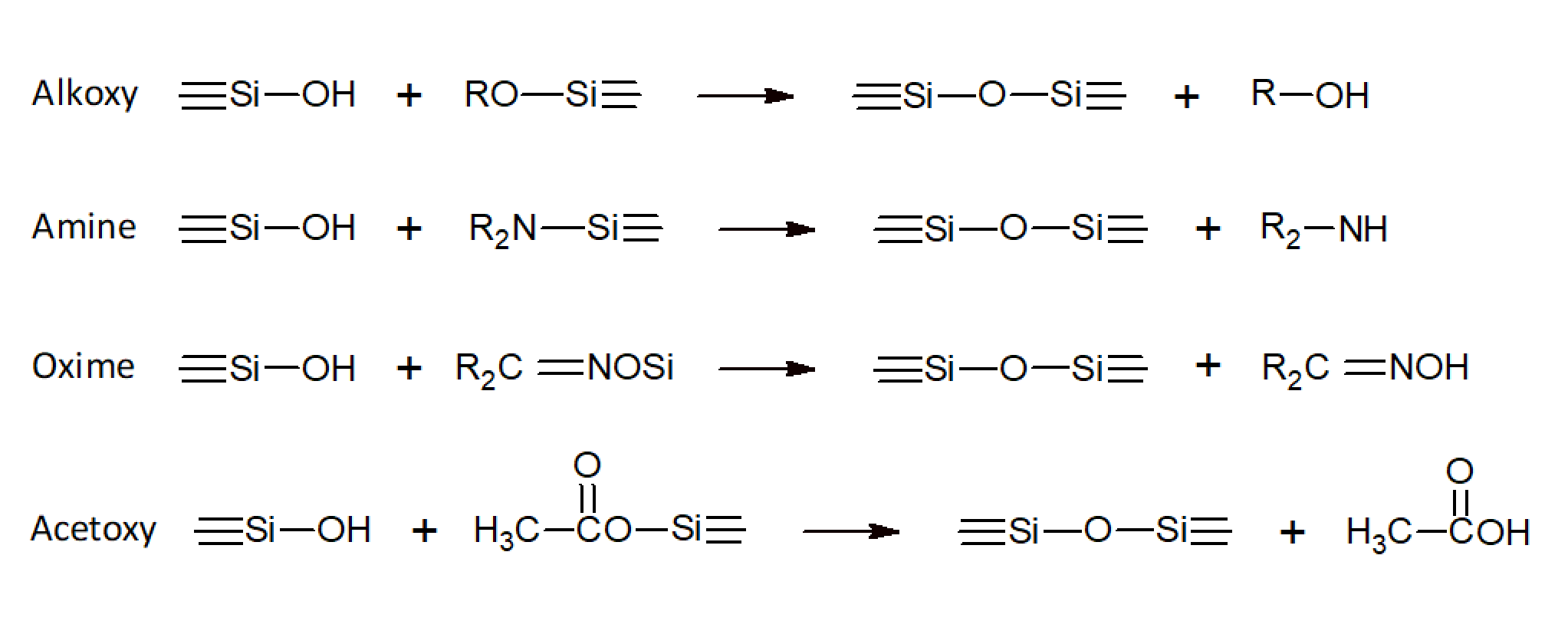

The silicone chemistry is remarkable versatile because silanol groups readily react with many

other functional groups such as acetoxy, oxime, amine, or alkoxy:

The crosslinking of alkoxy resins can be catalyzed by many metal-organics or acid/base catalysts, whereas one-part acetoxy resins are typically cured with tin catalysts and vinyl terminated resins with organic peroxides or platinum catalysts.

Commercial Polysiloxanes

Major producers of slicone rubbers and silicone resins are Dow Corning, Momentive, Gelest, Evonik, Bluestar, Shin-Etsu, and Wacker.

Applications

The simultaneous presence of “organic” groups attached to an inorganic backbone gives silicones a combination of unique properties and allows their use in fields as different as aerospace (low and high temperature performance), health care (excellent biocompatibility), consumer goods (kitchen ware), electronics (electrical insulation), or in the building industries (resistance to weathering). Major applications include masonry protective coatings, sealants, adhesives, surfactants, pressure sensitive tapes, antifoam agents, paper coatings, silicone fluids, mold-release agents, textile finishes, and silicone rubber molds.